|

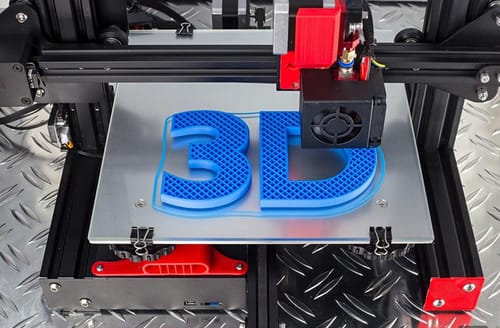

| Ford wants to use 3D printing waste |

Ford continues to lead in the future of 3D printing for cars, this time in partnership with HP to innovatively reuse materials and parts in 3D printing and convert them into injection-molded parts for cars.

From a sustainability perspective, one of the advantages of 3D printing is that it creates less waste than traditional manufacturing capabilities.

Sustainability is a top priority for both companies. Through joint exploration, this has resulted in an environmentally friendly solution.

The injection-molded end part is more environmentally friendly without sacrificing the durability and quality standards demanded by Ford and its customers.

Injection-molded fuel line pins that connect to Super Duty F-250 trucks are made from reclaimed materials.

Compared with the traditional version, these parts have better resistance to chemicals and moisture, the weight is reduced by 7% and the costs are reduced by 10%.

The Ford research team has identified 10 other fuel hose screws in existing vehicles that could benefit from using this innovative material and transferring them to future models.

Ford said: Ford is excited to find new ways to work with sustainable materials and reduce waste. Many companies are looking for significant applications of 3D printing technology. However, we with HP are the first to discover potentially interesting high-quality waste processing applications. Corporate program. Go to the landfill and turn it into functional and durable auto parts.

HP 3D printers are designed to be functional. Its system and structure allow for minimizing excess substances and most of the materials it contains can be reused.

Ford Motor Company has worked with Ford, which is using HP's 3D printing technology at its Advanced Manufacturing Center, to develop a waste-free solution.

"Our collaboration with Ford expands the environmental benefits of 3D printing and shows how we can integrate different industries to better benefit from manufacturing consumables," HP said.

Ford is developing new applications and using many different processes and materials for 3D printing, including liquefaction of filaments, sand, powders, and solids.

The company uses 3D printing of various parts and accessories for low-volume commercial vehicles used by assembly line workers. This saves time and improves quality.

Across the company, Ford plans to use 100% sustainable materials in its cars.